Our underground mining solution provides exceptional data capture

The collection of production data is vital for an underground mining solution as it assists with understanding what areas of performance throughout the mine can be improved.

MICROMINE’s underground mining solution, Pitram records data related to equipment, personnel and materials, providing an overall view of the current mine status. Pitram has several options for capturing production data in an underground mine with each method providing various benefits.

Simplicity in data entry

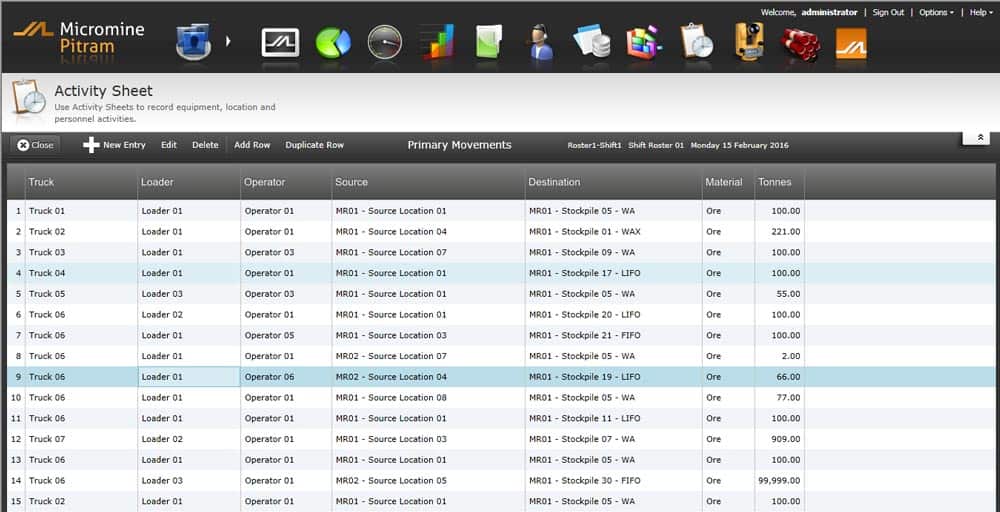

The most cost efficient method available in Pitram is manual data entry. Using the activity sheet module, equipment operators are able to manually enter data during their shift which is then entered into Pitram at the end of their day by data clerks. The user interface of activity sheet is designed to replicate the paper PLOD sheets used by the equipment operators. One of the key benefits of using the module is that it minimises any additional processes that may delay machine operators from their priority functions. Data can then be entered at a time suitable to the mining operation.

Pitram is also able to capture production data via radio communication between machine operators and the control room. Using the mine’s radio infrastructure, operators relay information to personnel in the control room who enter the live data directly into Pitram. The real-time reporting of data ensures data accuracy and allows for real-time decision to be made if necessary. The ability to make decisions in real-time is particularly useful in an underground operation due to space and safety constraints and. Captured data can then be analysed at the end of the shift for insight into operator performance. Radio communication is another cost effective means of data capture as reporting can be achieved through the existing radio network, eliminating the need to establish new infrastructure. It also provides better insight into a live mining operation than what spreadsheets or other manual processes can and is an ideal underground mining solution for data capture.

Underground mining solution: enhancing efficiency through automation

Automated data capture enables mining operations to optimise their key mining activities by reducing the disruptions caused by manual data entry, giving live information to the control room for decision making and providing near 100% accuracy. Pitram provides automated data capture via Pitram’s mobile module which serves as an underground mining solution for data capture. Using a Pitram mobile or tablet device installed in equipment cabins, operators enter data via touchscreen. When the device reaches Wi-Fi range, the data is then automatically uploaded to the Pitram database for analysis and reporting. Automatic data entry greatly reduces call volumes across the radio network which assists with increasing safety and production by allowing urgent information to be relayed without disruption. As a scalable solution, the capability of Pitram’s automated data capture can be enhanced by integrating with third party systems to gain access to data related to equipment health, loader utilisation and proximity detection.

Customise your software with Pitram

Pitram’s various data capture options provide underground mining operations with a more efficient method than manual data entry. They implementation can assist with the accurate capturing of data and highlight Pitram’s flexibility as an underground mining solution.

Further reading

>Learn more about Pitram’s underground mining solution.