Efficient material transfer through payload monitoring

Why is payload monitoring vital for mining operations? As each truckload has an ideal weight that minimises cost and maximises profit, trying to get as close to the target number is important for maximising the efficiency of your operation. Additionally, its important to ensure that the target weight is not exceeded as overloading trucks can increase maintenance costs and run the risk of costly spillages on haul roads. In an effort to maximise truck usage, operations can implement a payload monitoring system to track material being loaded for hauling.

MICROMINE’s fleet management and mine control solution, Pitram, uses mine design, survey and production data to provide real-time stockpile balances throughout the mine. Using Pitram enables operations to have greater control over their mine. Increased control allows operations to increase their production and reduce operational costs.

Analysing on-site material movement

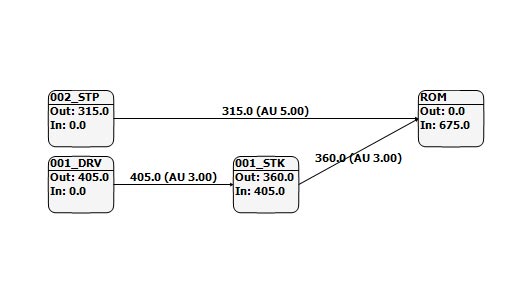

Pitram provides payload monitoring functionality via the materials management module. The module provides updated stockpile balances following every material movement ensuring the accurate location and value of available material is known at all times. Using the available tools in the materials management module allows sites to better manage and analyse on-site material movement to the mill.

Using Pitram enables supervisors to view the current levels of stockpile for any available location throughout the operation. User defined minimum and maximum levels can be defined that will alert supervisors when a stockpile has been overfilled or depleted. All material movements are recorded in Pitram and validated against a set of rules to ensure the integrity of data that has been entered and rectify any possible errors. These rules include identifying movements to or from an invalid location, movement to a primary location and stockpiles reporting a negative inventory.

Payload monitoring: managing inflow and outflow

When material reaches the mill, Pitram’s payload monitoring allows users to reconcile deliveries back along the material flow to ensure the recorded inflow and outflow of material is accurate. This process allows differences to be identified down to the individual material movement, allowing recording or measuring errors to be identified and rectified.

To ensure the maximum usage and most profitable use of your hauling trucks, utilising a fleet management solution like Pitram that has payload monitoring capability is key to meeting these standards.

Further reading

>Learn more about Pitram’s payload monitoring solution.