Mining material management tracking capabilities

Mining material management is a key to mine site performance and profitability. With the amount of material mining operations extract, keeping track of stockpile balances is important to ensure that the location and value of available material is known at all times.

MICROMINE’s leading fleet management and mine control solution, Pitram, provides the capability for mining material management via the materials management module. The module utilises mine design, survey and production data to provide real-time stockpile balances and metal stocks throughout the mining operation.

Mining material management: optimising material management software

The materials management module gives users a range of comprehensive and easy to use tools to analyse on-site material movement as well as mining material management from extraction locations to the mill feed stockpile. This allows reports to be generated for key areas of mining material management such as grade management and material reconciliation.

Pitram allows users to import location grades from mine design information to be redefined from assay results as they become available. These grades are combined with material movements that are also recorded in Pitram, to calculate the grade of each material as it moves through the mine.

Efficient and accurate stockpile solutions

Pitram is also able to provide real-time stockpile balances throughout the operation using the materials management module. Supervisors can assign minimum and maximum stockpile levels that will alert the control room when a stockpile is overfilled or depleted. Stockpiles can then be calibrated following grade surveys to ensure the most accurate representation of the mine’s stocks are available to view at all times.

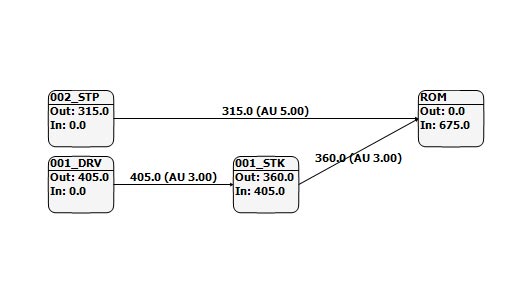

Using Pitram’s reconciliation functionality, material deliveries to the mill can be reconciled back along the material flow by segregating the material flow. The recorded inflow and outflow tonnage and grades can be compared to the mill report and if there are any discrepancies, they can be addressed. This process highlights Pitram’s capability as mining material management software by allowing differences to be identified down to the individual material movement level which assists with identifying and rectifying any errors.

Choosing Pitram for your mining material management:

For operations wanting real-time mining material management, Pitram provides a range of comprehensive and easy to use tools for reporting and managing mining material. Pitram improves operational control, allowing mining operations to increase their efficiency and reduce costs.

Further reading

>Learn more about Pitram’s mining material management software.