Improve safety with drill and blast mining module

Improve safety with drill and blast mining module

With the continuous development of mining software, mining companies are improving the control they have of their mine site as new technology provides capability to monitor the various mining operations. Increased control allows mining companies to increase production, reduce costs and improve safety standards across the site.

MICROMINE’s leading fleet management and mine control solution, Pitram’s drill and blast module, provides the tools required to assist with drill and blast mining tasks on-site. These tools provide improved control for mine supervisors which help to increase production and reduce costs.

Planning and scheduling

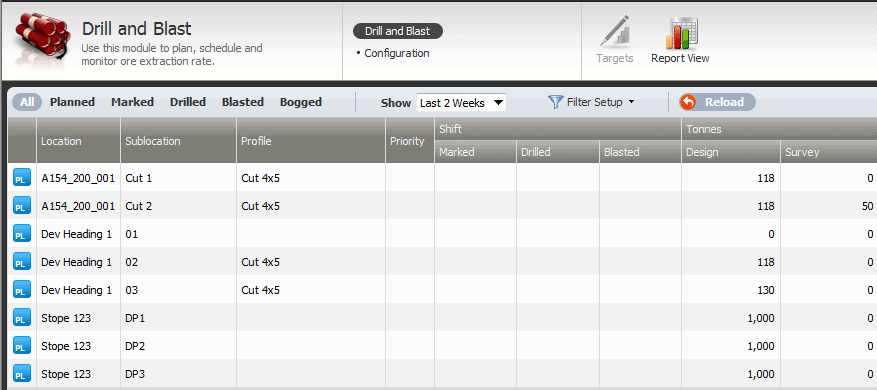

The scheduling functionality within the module gives operators control over the planning and scheduling of drill and blast mining tasks. Tasks can be scheduled based on the most efficient plan to ensure maximum efficiency. If a task needs to be rescheduled to avoid delaying other tasks, the control room is able to adjust accordingly, ensuring that the operation continues to run smoothly.

Extracting relevant data

Pitram also has extraction and ore removal monitoring which assists with gathering information about the resources that have been blasted. Data related to the type of resource being extracted, the remaining quantity and the quality is collected during the blast phase and presented to users in visual format. Pitram focuses on the presentation of the data in visual format as MICROMINE believes visual representation provides users with a more efficient understanding of what is occurring, reducing the time it takes to make decisions.

Drill and blast mining: enhancing cost efficiency

The drill and blast module has reporting functionality for when grade dilution begins to occur during blasting. In an underground mine, adjustments can allocate user-defined dilution types that will affect the weight and grade of available material. In an open pit mine, a single blast will create a number of material sources. When the design weight for the source is exceeded, the drill and blast mining module will give the geologist the opportunity to allocate a grade to the excess material. If the grade of the material is no longer viable to mine, geologists know it is time to move onto the next blast hole and not pursue a cost inefficient section of the mine.

Pitram can also report on drill holes, allowing users to see the plans for each drill hole, if they are ready to be charged, the amount of material that has been removed and the remaining stock available at any given time.

Choosing Pitram

Using Pitram will provide more control over your drill and blast mining tasks which assists with improving the efficiency of your operation.

Further reading

Learn more about Pitram’s drill and blast mining solutions.